In today’s digital age, where visual appeal and tactile experience are paramount, specialty printing techniques offer a unique way to make printed materials stand out. Specialty printing techniques like embossing, foil stamping, letterpress, and others not only enhance the aesthetics of a print job but also add a layer of sophistication and tactile appeal. In this blog post, we’ll explore several specialty printing techniques, highlighting their benefits and discussing the types of print jobs best suited for each.

Embossing

What is Embossing?

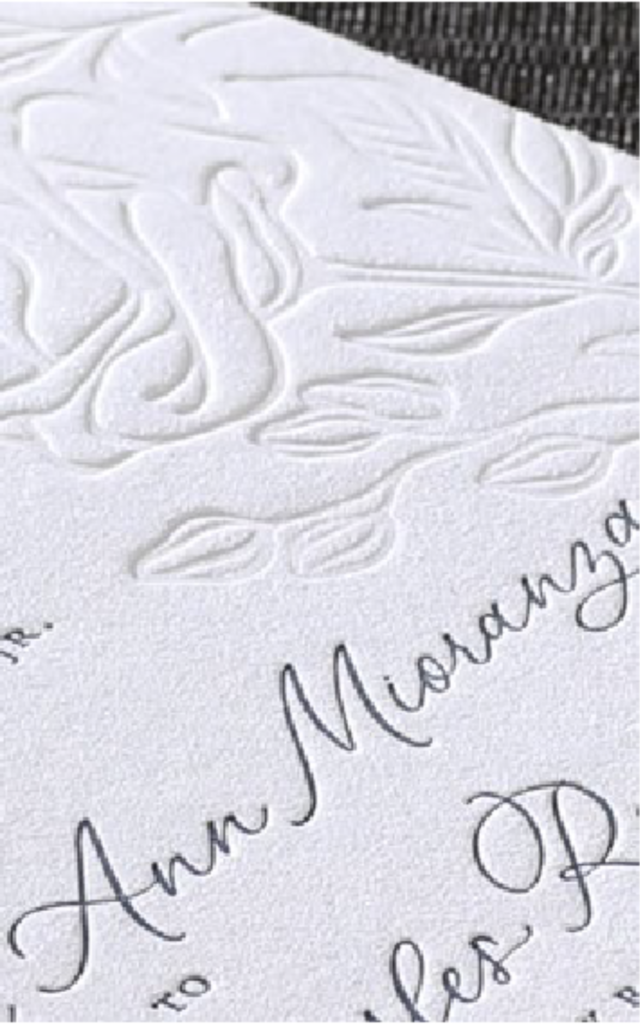

Embossing is a technique for creating a raised design on paper or cardstock. It is achieved by pressing the paper between two molds, one with a raised design (the die) and one with a recessed design (the counter die). When pressure is applied, the paper is molded to the shape of the dies, creating a raised effect.

Benefits of Embossing:

- Tactile Appeal: The raised embossing surface provides a tactile experience that engages the sense of touch, making the printed material more memorable.

- Visual Elegance: Embossing adds a three-dimensional effect to the print, giving it an elegant and sophisticated look.

- Versatility: This technique can be combined with ink or foil stamping or used alone, offering a range of creative possibilities.

Best Uses for Embossing:

Embossing is ideal for high-end business cards, stationery, invitations, and packaging. It’s particularly effective for logos, monograms, or any design element that benefits from a raised appearance. For instance, wedding invitations often use embossing to create a luxurious and elegant feel.

Foil Stamping

What is Foil Stamping?

Foil stamping is a printing process that uses heat, pressure, metal dies, and foil film to create shiny, metallic designs on paper. The foil is pressed onto the paper using heated dies, leaving behind a metallic print that can range from gold and silver to vibrant colors and even holographic effects.

Benefits of Foil Stamping:

- Luxurious Finish: The metallic sheen of foil stamping adds a sense of luxury and high quality, instantly elevating the perceived value of the printed piece.

- Attention-Grabbing: Foil stamping catches the light and draws attention, making it perfect for elements that need to stand out.

- Durability: The foil is resistant to wear and tear, ensuring the design remains intact for a long time.

Best Uses for Foil Stamping:

Foil stamping is perfect for business cards, invitations, certificates, book covers, and packaging. It’s especially effective for emphasizing key details like logos, borders, or titles. Corporate branding materials and luxury packaging often use foil stamping to convey a sense of prestige and exclusivity.

Letterpress

What is Letterpress?

Letterpress printing involves pressing an inked, raised surface against the paper, leaving a slightly indented print. This traditional technique dates back to the 15th century but has resurged in popularity due to its vintage appeal and high-quality results.

Benefits of Letterpress:

- Distinctive Look and Feel: The slight indentation left by the letterpress process creates a tactile sensation that is unique and pleasing to the touch.

- Timeless Quality: Letterpress has a classic and timeless appeal, often associated with high-quality craftsmanship.

- Customization: It offers the ability to print on thick paper stocks and allows for a range of ink colors, including metallics.

Best Uses for Letterpress:

Letterpress is ideal for wedding invitations, greeting cards, business cards, and any print project where a premium, handcrafted look is desired. It’s also popular for small-run art prints and boutique stationery.

Spot UV Coating

What is Spot UV Coating?

Spot UV coating is a technique where a clear, glossy coating is applied to specific areas of a printed piece. This coating is then cured with ultraviolet light, creating a shiny, raised effect that contrasts with the matte finish of the surrounding areas.

Benefits of Spot UV Coating:

- Visual Contrast: The contrast between the glossy coated areas and the matte background creates a striking visual effect.

- Highlighting Details: Spot UV is perfect for drawing attention to specific elements like logos, images, or text.

- Durability: The UV coating adds a layer of protection to the printed piece, making it more resistant to wear and tear.

Best Uses for Spot UV Coating:

Spot UV is frequently used on business cards, brochures, postcards, and packaging. It’s especially effective for highlighting logos or key images, giving them a stand-out, glossy shine against a matte background.

Die Cutting

What is Die Cutting?

Die cutting is a process that uses a sharp steel blade to cut paper or cardstock into custom shapes. Dies are custom-made for each project, allowing for intricate and precise shapes that standard cutting methods can’t achieve.

Benefits of Die Cutting:

- Custom Shapes: Die cutting allows for the creation of custom shapes and designs, adding a unique element to the printed piece.

- Enhanced Creativity: The ability to cut out shapes or windows opens up endless creative possibilities for designers.

- Professional Finish: Die-cut pieces have a clean, professional finish that elevates the overall quality of the print job.

Best Uses for Die Cutting:

Die cutting is perfect for creating unique business cards, invitations, brochures, labels, and packaging. It’s often used for promotional materials and marketing pieces that need a strong visual impact.

Thermography

What is Thermography?

Thermography is a printing process that involves applying a special powder to wet ink on the paper, which is then heated to create a raised, shiny surface. This technique is often used as a more affordable alternative to engraving.

Benefits of Thermography:

- Raised Effect: Similar to embossing, thermography creates a raised effect that adds texture and depth to the print.

- Cost-Effective: It offers a more budget-friendly option than engraving, while still providing a high-quality finish.

- Variety of Colors: Thermography can be done in a wide range of colors, including metallics, offering versatility in design.

Best Uses for Thermography:

Thermography is commonly used for business cards, invitations, letterhead, and certificates. It’s an excellent choice for projects where a raised print effect is desired without the higher costs associated with embossing or engraving.

Specialty printing techniques like embossing, foil stamping, letterpress, spot UV coating, die cutting, and thermography provide a variety of options for enhancing print projects. Each offers unique benefits, from adding tactile appeal and visual contrast to creating custom shapes and adding a luxurious finish. Choosing the right technique for your print job can create memorable, high-impact materials that effectively convey your brand message and leave a lasting impression. Whether you’re designing business cards, invitations, packaging, or promotional materials, these specialty printing techniques can help elevate your project to the next level.

Our team at OMNI Print is here to help. We offer a range of high-quality printing services and are dedicated to making your vision come to life. Contact us today to get started on your next project!